Control room simulators vary from plant to plant across the fleet, but none were able to simulate or train operators on how to use the market reporting compliance tools, called Sentinel, without doing on-the-job learning with live systems which comes with inherent risks. Bespoke systems could be created although none had been deemed a cost-effective solution.

The UK energy industry is heavily regulated, with significant fines levied against energy wholesalers who fail to meet compliance responsibilities around reporting expected output against supply and market rates and demands. EDF Energy needed to be able to train their power station control room operators to use the robust but aging Sentinel for this purpose.

Make Real explored various hardware and software options before defining a unique, cost-effective solution that combined off-the-shelf low-cost electronics that could be easily sourced and integrated into a visually accurate simulation of the Sentinel software.

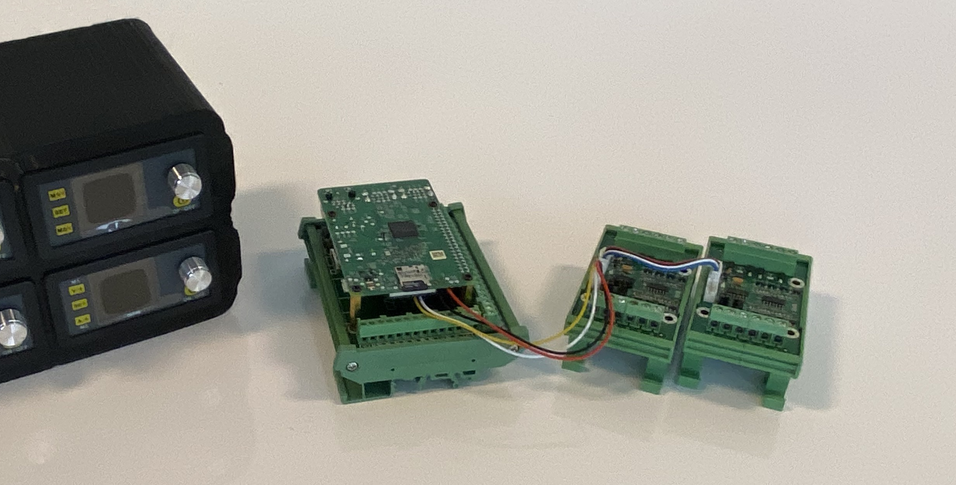

Hardware comprised of a Raspberry Pi and bespoke network bridge PCBs to convert analogue outputs from the control room power station simulator into digital signals to be fed into the software simulation.

Many forms of testing were required since the end deployment was potentially safety critical and required the range of compliance factors to be met as per regulatory body standards. Operational uptime was paramount so the test systems were extensively soak tested before installation on one control room training site, where necessary connections between simulator, control room systems and the instructor station were plumbed in. The simulation of the reporting tool was then validated by the learning team and real world operators. Once signed off at that stage, the instructor controls over the simulated events for training were reviewed and embedded into the training schedules.

The Make Real team undertook a series of site visits to nuclear power station control room training centres to capture relevant information and details of the Sentinel software reporting tool, meeting with the training team, operators and market reporting team to understand current procedures and pain points in training, instructor station requirements and operational procedures.

Software design and development of the simulated software reporting tool was completed in Unity, along with the instructor station control application to allow simulated events in the control room to be triggered and monitored, either as pre-configured situations or custom events designed by instructors in the future.

PCB design started off as breadboards, determining components connections and data pathways around the network bridge operations of analogue to digital signal conversion, before being manufactured with pro high-tech tooling to meet electrical and standards compliance levels of their own.

The solution has so far been rolled out across nine power stations across the EDF fleet nationwide, with more training centres expected to come online.

By designing an innovative solution utilising off-the-shelf components with bespoke software simulation integrated into the control room training centre and instructor station, six-figure development costs have already been saved, compared to options offered by existing simulator providers.

Whilst in its early days still, the expected benefits are a combination of commercial and social. Commercially the aim is to reduce the number of non-compliance events and resulting fines. As a socially-responsible company, EDF Energy looks to always improve public perception of the power generation industry, especially around nuclear, through better training, compliance and public outreach programmes.

An additional benefit beyond the reduction in non-compliance events and associated fines, the project and subsequent training of the control room training team across the country, has forged closer links and unification of procedures throughout the fleet training centres.

EDF Energy – Sentinel won Learning Technologies Awards 2019 – ‘Most Innovative New Learning Technologies Product – UK’ (silver), with the judges commenting:

“It has always been a challenge for organisations to replicate hardware into simulations without vast cost, but Make Real did some serious ‘outside-the-box’ thinking and came up with a clever, fascinating and low-cost solution that is scalable across EDF Energy’s organisation and clearly delivered their business goals. Judges were impressed by how the hardware and software integrated to simulate daily procedures and how it extended the functionality of hardware simulators already in use at EDF.”

We’re always happy to talk to you about how immersive technologies can engage your employees and customers. If you have a learning objective in mind, or simply want to know more about emerging technologies like VR, AR, or AI, send us a message and we’ll get back to you as soon as we can.